- Home

- Equipment Display

- AOI for IC Packaging

Machine features

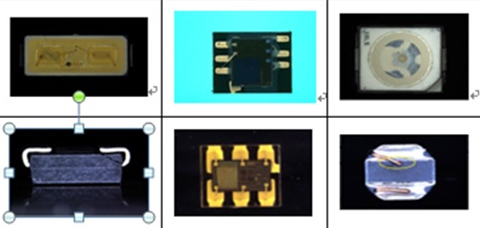

IC packaging products include DIP (dual in-line package), SIP (single in-line package), SOP (small package), TSOP (thin small package), QFN (quadron flat no-lead package), BGA (ball grid array package), PGA (pin grid array package), and the delicate and cumbersome inspection work can be handed over to the wafer visual inspection machine instead of manual inspection, greatly improving work efficiency.

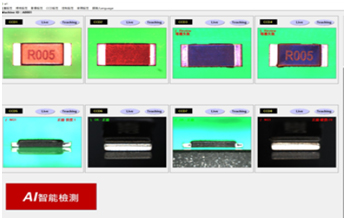

The visual inspection of IC packaging products by the automatic optical inspection machine is mainly on the body and lead brackets, and focuses on the detection rate. TFCT has an AOI+AI detection solution that can improve the detection rate of products, combining the respective expertise of AOI and AI for detection, so as to maximize the detection rate.

- Inspection materials: Various specifications of semiconductor chips (QFN ; ODFN ; SMA ; LTCC…) and other chip-type components

- Inspection size: 1mm ~ 13mm

- Inspection defects: Various size inspections, various damaged and missing corner inspections, various text and graphic inspections; air bubbles, copper leakage, sundries, contamination, tin, electrode damage, excessively long wire tails, missing soldering, missing wires, multiple (convex) glue, missing (Concave) glue, overflow glue, cracks, tin connection...; testing items can be freely increased or decreased according to require

- Inspection sides: 4 / 6 / 8 sides (optional station, eight more than two CCD can detect different abnormalities)

- Throughput: 2000 pcs/min <300,000 pixels>; 1000 pcs/min <1.3 million pixels>; 600 pcs/min <2.3 million pixels> (depending on material size and testing items)

- Sorting boxes: OK box (1), different NG box (3/4), rework box (1), residual material box (1)

- Resolution: 1.5μm/pixel(01005), 3μm/pixel(0201), 5μm/pixel(0402), 8μm/pixel(0603), 10μm/pixel(0805)*High resolution base

- CCD: color high-speed CCD 640*480 pixels

- Lighting: LED light source (different light source is provided according to the material)

- Operating height: about 1100mm

- Machine color: ivory white + iron gray

- Power supply: 1ϕ 220V 50/60Hz 1A

- Machine Size: L92*W92*H180cm

- Machine Weight: 450kg

- Main Controller: PC / HMI / Vibration Plate Controller / Front Panel

- Language display: English / Chinese

- Screen display: PC: 22"LED monitor; HMI: 7"

- Emergency stop: located on the front panel (push button)

- Backup: install a hard disk for backup.