- Home

- Equipment Display

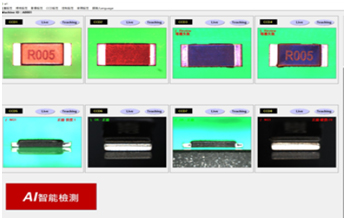

- AOI for Passive Components (Resistor, Inductor, Capacitor)

Machine features

The visual inspection machine for passive component equipment include inductors, resistors, and capacitors. Capacitors include single-layer ceramic capacitors and multi-layer ceramic capacitors (Multi-layer Ceramic Capacitors, MLCC).

Regarding the important features of passive component visual inspection equipment, not only the detection rate, but also high production speed is its characteristic. The patent of TFCT's pulse wave high-pressure material guide system is specially developed for materials with small volume and high speed. Therefore, the production speed of the six-sided appearance inspection is:

- 01005 - 10000pcs/min

- 0201 - 8000pcs/min

- 0402 - 6000pcs/min

- Inspection materials: MLCC, BEAD, VARISTOR, INDUCTOR, LTCC, R

- Inspection size: 01005~1206 (subject to actual measurement)

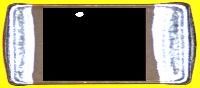

- Inspection defects: poor product position, electrode width, electrode length, electrode interval, electrode mold black, electrode peeling, poor electrode plating, electrode and electrode, body width, body length, body staining, body contamination, body defect, Body scratches, body discoloration

- Inspection sides: 4 / 6 / 8 sides (optional station, eight more than two CCD can detect different abnormalities)

- Throughput: 10000pcs/min(01005C); 8000pcs/min(0201C); 6000pcs/min(0402C); 4000pcs/min(0201R~0402R)

- Sorting boxes: OK box (1), different NG box (3/4), rework box (1), residual material box (1)

- Resolution: 1.5μm/pixel(01005), 3μm/pixel(0201), 5μm/pixel(0402), 8μm/pixel(0603), 10μm/pixel(0805)*High resolution base

- CCD: color high-speed CCD 640*480 pixels

- Lighting: LED light source (different light source is provided according to the material)

- Operating height: about 1100mm

- Machine color: ivory white + iron gray

- Power supply: 1ϕ 220V 50/60Hz 1A

- Machine Size: L92*W92*H180cm

- Machine Weight: 450kg

- Main Controller: PC / HMI / Vibration Plate Controller / Front Panel

- Language display: English / Chinese

- Screen display: PC: 22"LED monitor; HMI: 7"

- Emergency stop: located on the front panel (push button)

- Backup: install a hard disk for backup.

Body contamination

Body over solder

Body peel off

Body chipping

Residue or solder fines

Silver paste or solder fines

Crack